Electrical Safety is paramount while working on live equipment. It can cost us life, equipment and even entire surrounding. This is one of the most important aspect that we need to cater for before anything else. This post will discuss Electrical Hazards, importance of Test Equipment Safety, Safety Categories, Electrical Safety Standards and Safety Checkoff List.

Electrical Safety Failures

“While 1 mA of electric current can feel like a faint tingle, anything between 50 and 150 mA can cause extreme pain, respiratory arrest, and severe muscle contractions. 10,000 mA and above can lead to instant cardiac arrest, severe burns, and death.”

Electrical Safety Foundation International (EFSI), a non-profit, has actively promoted electrical safety across North America. According to their report on workplace injury and fatality due to electrical hazards statistics, there was an 18% rise in fatal electrical injuries between 2017 and 2018, which were caused by shocks and arc flashes.

On Dec 18, 2019, there was a power outage in Spearfish, South Dakota. Two engineers of the Butte Electric Collective who grounded an electrical fuse by mistake, causing the power outage, were admitted with facial burns.

Publications in the electrical industry have emphasized the use of proper tools for energized and de-energized work, and correct Personal Protective Equipment (PPE). However, not much is spoken about improving safety when using electrical test equipment and instruments.

Some of the commonly used electrical test equipment are non-contact voltage testers, multimeters, insulation testers and ground resistance testers.

Electrical Hazard

An Electrical Hazard is defined as any unsafe condition in which a worker/operator may or does make electrical contact with energized equipment or a conductor.

Common Electrical Hazards

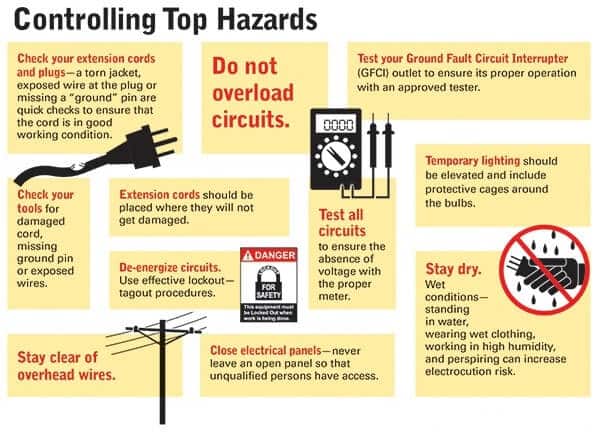

Some common types of electrical hazards include:

- Exposed Live Wires

- Damaged Wire Insulation

- Exposed Electrical Parts

- Fire due to faulty Wiring

- Wet Surroundings

- Overload

- Faulty Grounding

- Inadequate Wiring

- Improper Electrical Tool

Injuries Due to Hazards by Failures in Electrical safety

Following are the 5 types of injuries that engineers working with test equipment are exposed to. These are:

- Electric Shocks

- Electrocution (fatal)

- Burns

- Falls

- Explosions (especially if they are working in an environment with explosive gases and vapors, and combustible dust)

These injuries can happen in various ways such as:

- Direct contact with energized electrical or testing equipment can cause electricity to flow through your body causing muscle spasms, and irregular heartbeat and breathing.

- Electricity can arc from energized conductors or overhead high-power electric lines, and pass through the body of a person who is grounded.

- Electric arcs can cause severe thermal burns on the skin. Contact burns from shocks can burn internal tissues without being visible on the skin.

- Ultraviolet (UV) and Infrared (IR) light emitted from arc flashes can damage eyesight.

- Pressure waves released from an arc blast can cause physical injuries, collapsed lungs, or damage hearing.

- Electrical engineers can fall from scaffolding or ladder due to muscle contractions and startle reactions caused by shocks, causing physical injury.

First Aid Treatment in Electric Shock – Causes, Sources, SeverityWhy & When is Electrical Test Equipment Safety Check Important?

The simple reason is to safeguard the engineers and end-users. Consider the case of a mobile phone. As a standalone device, it is not much of a threat. But once it is connected to a charger and a power socket, it can be a potential source of electrical shock if the insulation were to fail. The same goes for any electrical circuit in a manufacturing unit, power plant, laboratory, or a workshop that does testing of electrical devices.

According to the Occupational Safety and Health Administration (OSHA), a shock hazard is possible where the potential is above 42.4 V, and the current through a 1,500Ω load is more than 5mA.

All electrical devices and circuits have to undergo a safety check after manufacturing and installation and during their life.

Global Verifications & Certifications for Electrical Safety

Following are some examples of the agencies responsible for global verification and certification of electrical devices and circuits including testing devices:

- Underwriters Laboratories (UL)

- Canadian Safety Association (CSA)

- Technischer Uberwachungsverein (TUV)

Once the agencies verify and certify that the testing equipment meets the safety requirements, the manufacturer puts a label on it to show that it is safe. The agencies are also responsible for routine inspections of the manufacturing facilities to assess compliance.

International Standards Applicable for Electrical Safety

When you procure electrical testing equipment, it is advisable to check if they comply with the global safety standards. International Standards applicable for electrical safety are as follows:

United States – NEC 2008 Table 250.122 – Safeco Electric Supply, NFPA, IEEE STD 80, IEEE STD 80, NFPA 496, NFPA 70

United Kingdom – British standard BS EN 61439, BS 5266, BS 5839, BS 6423, BS 6626, BS EN 62305, BS EN 60529

Canada – CSA Z462, CSA Z460-05

Australia – AS/NZS 3000:2007, AS/NZS 3012:2010, AS/NZS 3017:2007, AS/NZS 3760:2010, AS/NZS 4836:2011

Bulgaria – Български Държавен Стандарт – БДС 12.2.096:1986

Brazil – (BRA) Brazilian National Regulation – NR10

China – GB4943, GB17625, GB9254

Germany – IEEE/TÜV – NSR Niederspannungsrichtlinie 2014/35/EU

France – La norme français C 15-100 – Aspects de la norme d’installation électrique

India – IS-5216,IS-5571,IS-6665

Poland – PN-EN 61010-2-201:2013-12E

Russia – ГОСТ 12.2.007.0-75,ГОСТ Р МЭК 61140-2000,ГОСТ 12.2.007.0-75,ГОСТ Р 52726-2007

Understanding Electrical Safety Categories – CAT Ratings

The Overvoltage Installation Category is the single most important rating system available for engineers working with equipment in high power environments. Electrical testing equipment is now rated as per following CAT ratings:

- CAT I

- CAT II

- CAT III

- CAT IV

CAT I

This mainly applies to protected electronic equipment that is connected to sources with limited transient voltages. It also applies to high-voltage, low-energy sources derived from a high-winding resistance transformer.

CAT II

This applies to single-phase, receptacle-connected loads such as appliances, portable tools, other similar loads. It is also applicable to electrical outlets at more than 10 meters (30 feet) from a CAT III source and 20 meters (60 feet) from a CAT IV source.

CAT III

It applies to the three-phase distribution, including single-phase commercial lighting. Its practical applications can be seen in switchgear, polyphase motors, bus and feeder in industrial plants, lighting systems in larger buildings, feeders and short branch circuits, and distribution panel devices.

CAT IV

This rating is applicable for three-phase at utility connection and any high power outdoor conductors. Examples include electricity meters, primary overcurrent protection equipment, and service drop from pole to the building.

Electrical Safety Checklist for Working on Electrical/Test Equipment

Broadly speaking, electrical safety is a combination of using the right equipment and protective gear, having a skilled engineer do the job, and a safe working environment. Here is a detailed checklist that you can follow:

- Work on de-energized circuits with lock-out and tag-out procedures in place. Refrain from working on energized circuits as much as possible.

- Use Ground Fault Circuit Interrupters (GFCI) in wet or damp areas so that they can interrupt the circuit before it can cause injury or death.

- Use the latest electrical testing equipment with accepted safety standards and fused current inputs.

- Select the required function and range of your testing instrument before conducting the test.

- Inspect the surroundings for any high-current and high-voltage sources such as overhead power lines.

- Remove any metal pieces from your body such as jewelry and watch. Use PPE equipment and insulated tools:

- Safety glasses and face shields.

- Flame resistant clothing.

- Insulated mat.

- Electrical testing equipment with the right CAT rating.

Follow these steps when you have to test a live circuit –

- Clamp the ground clip first followed by the hot clip. Once testing is done, unclamp the hot clip and then the ground clip.

- Use a three-point testing method. Test a known live circuit first followed by the target circuit, and then the known circuit again. This ensures that your test equipment is working properly.

- Hang the test meter or stick it using a magnet at a place where it is easy to see the readings. Avoid holding it in your hands.

- Use alligator clips to clamp the black lead, and use only one hand to test with the red lead. This prevents electric current flowing through a closed-loop via your chest and heart.

Conclusion

It is important to keep ‘safety first’ when working in high-voltage environments or using electrical testing devices. In addition to procuring the right testing equipment, it is important to have it audited by the supplier at regular intervals for compliance with safety standards.

Using the right testing equipment that is rated for safety is just one of many important steps that can save lives and prevent unwanted business losses.

Also Read: Electric Field - Gauss's & Coulomb's Law, Electric Field Lines, Applications Smart Street Light System: Architecture, Working Principle, Applications First Aid Treatment in Electric Shock – Causes, Sources, Severity

December 8, 2022 @ 6:54 PM

“While 1 mA of electric current can feel like a faint tingle, anything between 50 and 150 mA can cause extreme pain, respiratory arrest, and severe muscle contractions. 10,000 mA and above can lead to instant cardiac arrest, severe burns, and death.”

10,1000 mA? Incorrect.